The terms asset tracking and real-time location systems (RTLS) are often used interchangeably. Both terms have to do with understanding where things are—finding the things that matter. In truth, asset tracking and RTLS are notably distinct, despite their regular overlap, so it can be difficult to distinguish between the two at first. However, it’s important to disambiguate when looking for either solution, because what you need from RTLS might not be inherent in asset tracking solutions and vice versa.

RTLS

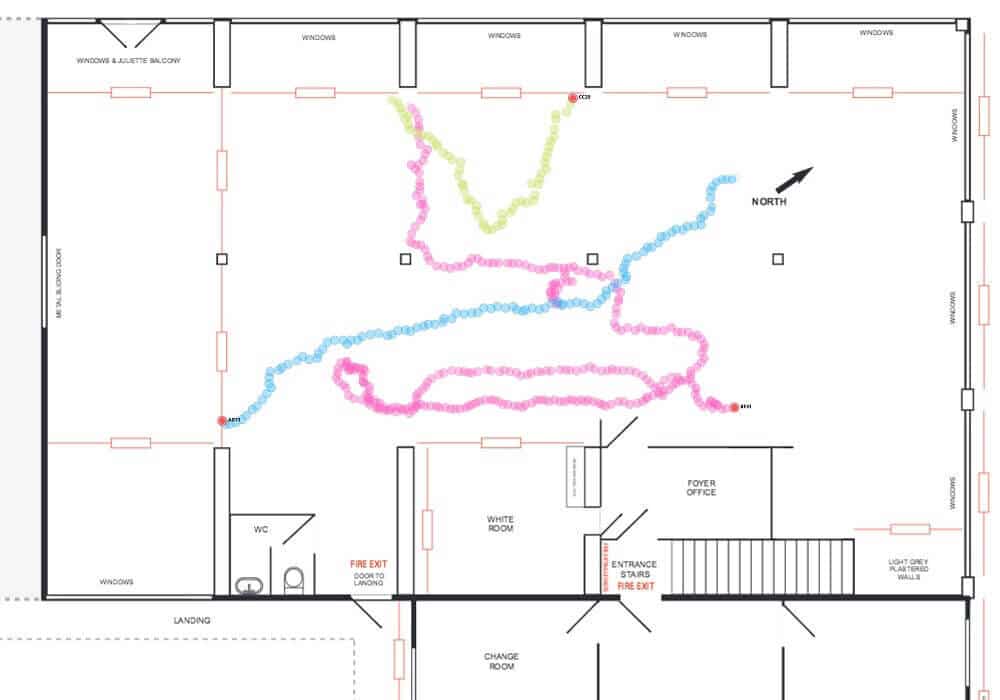

The term RTLS describes systems used to generate in-the-moment updates on the location of specific objects. Often referred to as the blue dot on the map, RTLS shows where something is at a given moment—not just where it was last logged or where it’s supposed to be.

You can essentially think of RTLS as quantifying what, where, and when.

One caveat: The real-time portion of RTLS can be a misnomer. Even the best RTLS will have some delay in determining and reporting location, no matter how miniscule. Such delays are inevitable because of both the time it takes to gather and process location data and the finite speed of any signaling / transmitting technology.

Many approaches to RTLS display location multiple times per second, which is frequent enough for nearly all RTLS applications. Other systems only report periodically, such as every several seconds or minutes, which can also be sufficient for many uses of tracking and location. Because no current system truly reports instantaneous location data, it’s important to clearly define any requirements for ‘real time’ when adopting RTLS.

Ultimately, the term real-time typically indicates that a system sends updates ongoingly and automatically, rather than only when initiated by a scan or other manual intervention.

As an example, one WISER customer wanted to generate heatmaps showing where key items or personnel moved in their factory. Their purpose wasn’t to increase accountability for or find missing assets—common focuses for asset tracking. Rather, this manufacturer’s goal was to use location data to optimize and streamline location-based processes—moving unfinished product from point A to point B, or employees moving between workstations for instance—without adding menial labor like frequent location scans. WISER’s ultra-wideband (UWB) RTLS offered the ideal tool to accomplish this.

Asset Tracking

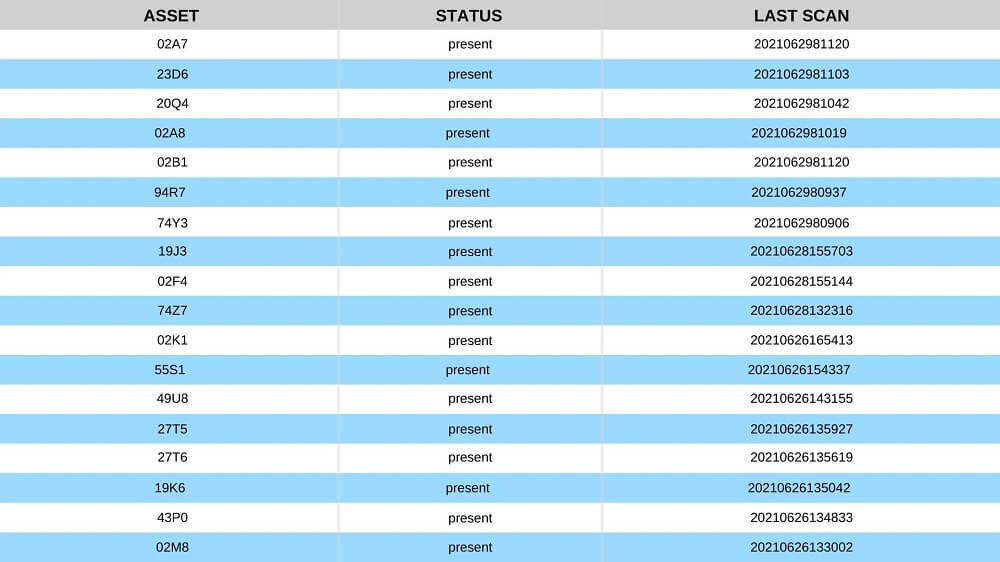

The term asset tracking denotes a system to monitor or update the status of various assets, especially physical ones. This usually relates to location in some way but is not always specific about where an asset actually is, let alone where it was at any given point in time. Furthermore, asset tracking does not necessarily report current—i.e. real-time—status of a given asset. Rather, asset tracking often refers to the status of a given asset at certain preset points.

In practice, asset tracking could take the shape of the blue dot on the map referenced above or simply describe a manifest of tracked assets and their last-known status, with many variations in between these two extremes.

Whereas RTLS identifies what, when, and where, asset tracking is primarily concerned with identification (what) and incorporates other types of data (where, when, who, etc.) less uniformly. Location, whether real-time or defined by at-rest / static endpoints, is an especially common component of asset tracking as well, but location data doesn’t always need to be continuous for an effective asset tracking system.

An extremely valuable example of non-RTLS asset tracking is the common system for global package tracking. Packages are outfitted with a barcode when the carrier first receives them, and the barcode is scanned at each major juncture of the journey, allowing package owners to track their locations from point of origin to in-transit to delivered. Location data is most often reported at transit-points involving a new scan, but this package tracking process only shows the package’s location at the time of the scan. In other words, package tracking keeps identification in mind at each juncture, but location data is never what we’d call real-time.

Another caveat to asset tracking: Most end users will draw some terminology distinctions between asset tracking (a very broad term) and specific applications of asset tracking technology. For example, fleet management, yard management, or forklift tracking could all be called simply asset tracking. Since they are more specific than the umbrella term asset tracking is by itself, however, it often makes sense to distinguish for these types of endeavors. Hence workers in the field might never once call these processes ‘asset tracking’ even when utilizing asset tracking systems daily.

The Intersection of Asset Tracking and RTLS

Where RTLS refers more to systems that generate location data, asset tracking describes the purpose for such data (and related metadata). So, in cases of overlap, you could say that asset tracking is often the goal behind RTLS.

In actuality, the majority of RTLS applications can be termed asset tracking as well. On the flip side, most asset tracking systems don’t rely on current location at all, so these would not be called RTLS.

It’s also worth noting that many instances of location data for navigation or personnel safety would qualify as RTLS without being termed asset tracking. For instance, indoor wayfinding in hospitals, museums, or other large facilities now uses RTLS in many cases. Likewise, tracking workers’ locations in hazardous settings like mines and refineries is becoming more common, using RTLS. When tracking people—not things—however, the term asset tracking is almost never used.

One easy place to see the intersection of asset tracking and RTLS is the tracking of bins, carts, or other containers of goods. It’s common to track riders of paperwork with moving pallets in a warehouse, as an example. It’s also typical to track work-in-progress through manufacturing by monitoring the location of associated work orders, which are often transported together in movable bins. The paperwork in both scenarios is part of the asset tracking system, since it provides the ability to scan and account for an asset’s journey. It’s also increasingly common for site managers to track the container of that paperwork itself (the rider or the bin) using RTLS. This way, individual components within the container can be tracked as batches, if they stay associated with the correct container, and whole containers can be tracked and traced in the moment using RTLS.

Other Connected Terms

In addition to RTLS and asset tracking, numerous other terms often get attached to or associated with one another, including but certainly not limited to:

- Asset management. This term most often refers to digital or financial holdings but can also describe the organization of physical things as delivered by an asset tracking solution.

- Inventory management. Unlike asset management, inventory management specifically describes the processes used to organize and optimize inventories of replenishable, movable things—physical things, often items intended to be sold or shipped out in time—so the term inventory management is often used in conjunction with asset tracking.

- Indoor positioning. While it’s synonymous with RTLS in some cases, indoor positioning only really describes a system for producing positioning data and insights in indoor settings. Indoor positioning is thus much more exclusive in nature than the term RTLS, which can describe operations in a wide variety of settings.

- RFID. Radio frequency identification (RFID) can be used to demarcate any radio / wireless RTLS or asset tracking system. Some organizations do use this term as a vague catch-all for radio-based identification systems. In practice, however, RFID ordinarily refers only to a specific category of wireless tag-and-reader systems.

Conclusion

Few terms connected to RTLS and asset tracking are consistently defined in practice. Furthermore, most of these terms are use-case or industry-dependent, making it more difficult to define what systems or technologies you may or may not need.

When disambiguating, it’s always helpful to ask: What are you trying to accomplish via this system or technology? If you can answer that clearly, it will usually be similarly clear what functionality and feature sets you need. From there, it’s easy enough to tell whether you need RTLS, an asset tracking system, or both.

Post originally by Stephen Taylor